TDC Structure : software for Technical Functional Analysis

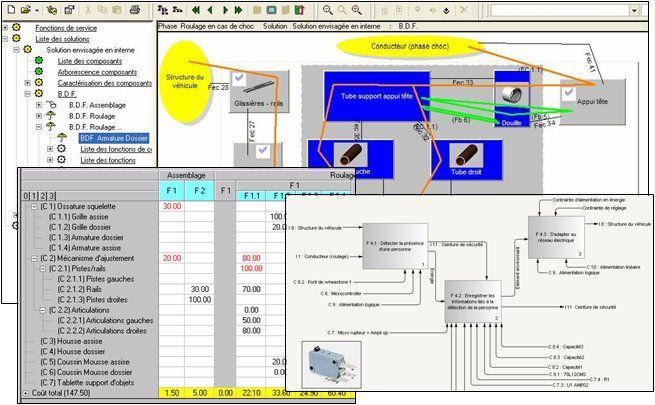

The ‘organizational’ view of the system : how to associate needs and solutions.

Internal Functional Analysis, FAST, SADT, Functional Block Diagram (FBD), Functional Analysis Chart (FAC), APTE® Method.

A formalized approach for Technical Functional Analysis

TDC Structure software enables to assign the service functions to the components of the different technical solutions devised by the designer. The objective is to optimize the (re) design of a product or system.

Retrieving if necessary the service functions defined with the External Functional Analysis TDC Need software, you can model your product using one of the three proposed methods:

-Functional Block Diagram (FBD) which allows to identify the internal technical functions (closed flow) induced by the design.

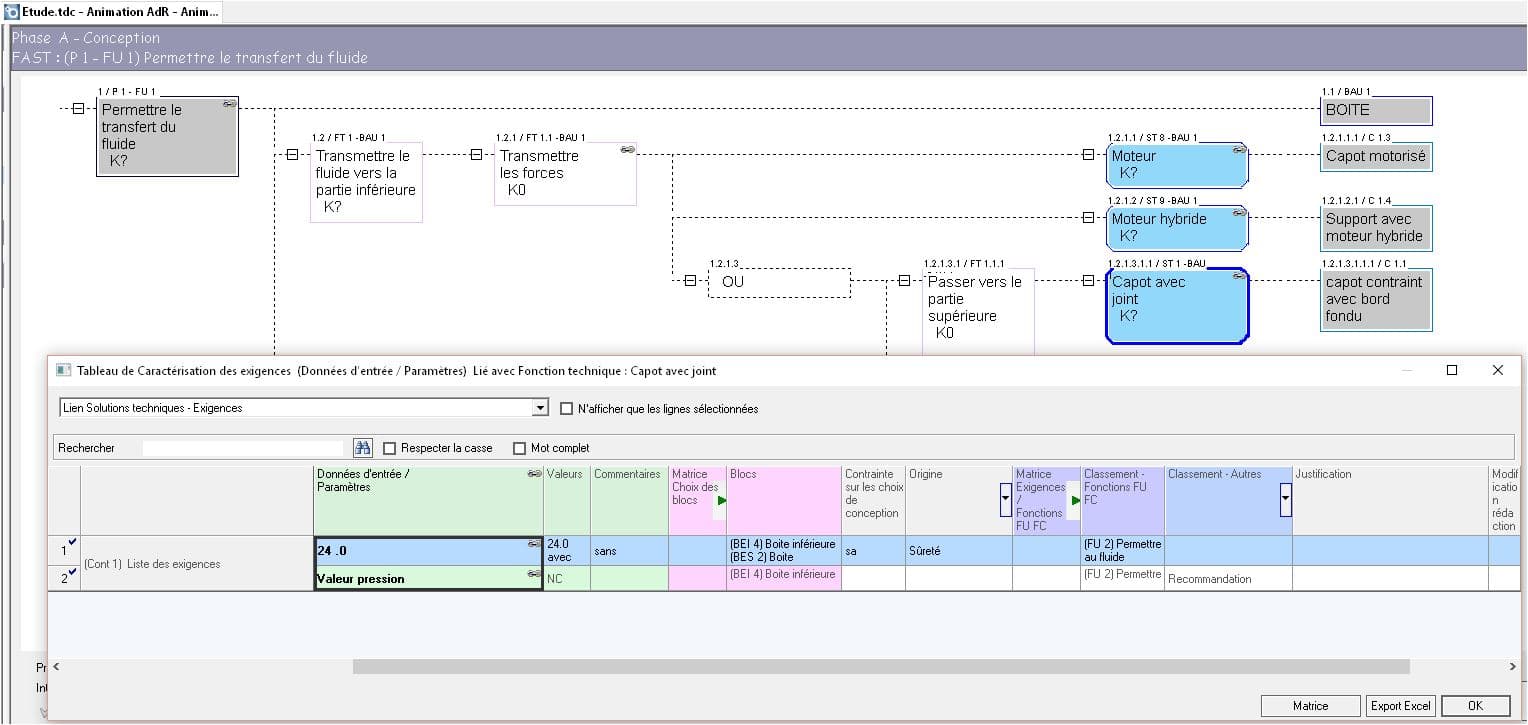

-FAST diagram that allows the designer to justify the technological pathways that have been studied and selected,

– or the SADT if you integrate e.g. electronics (input/output);

The Functional Analysis table (FAC) will then validate the FBD, the FAST or the SADT, and assign the costs of the components to the functions. This work can of course be performed at different levels of detail and will constitute the starting point for prospective risk studies: design FMEA – Process FMEA, or Fault Trees.

Facilitate the technical discussions during design

All the data (solutions, components, technical functions,…) are traceable. Thanks to the access to all the dates, authors and contents of the changes, you can, for instance, filter all data not having been changed since the latest project review or list up the successive evolutions of a particular task.

Improved responsiveness and development time

Using the videoprojector during the work sessions and tools such as components tree (classification), FBD, FAST and FAC facilitates the workgroup reflection. Responsiveness is also gained via performing and changing during the work session. Document and ‘to do’ action sharing helps gain efficiency between the work sessions

Engineering data consistency

The consistency of the engineering data is ensured by the data sharing between the various tools during the design process: External (FPS) and internal (FBD – SADT – FAC) functional analysis, Design FMEA, Process FMEA, control plan, process flowchart, specific features, fault tree, etc.

Features

- You can directly enter the data into the product environment and the service functions into their life steps, or retrieve them from TDC Need and place them on the FBD graph (Functional Block Diagram), in the FAST or SADT.

- Create the product classification,features of the components on the FBD contacts .

- You can assign service functions to the components and create closed flows (technical functions).

- Functional Block Diagram and / sub-Functional Block Diagram link; SADT on different levels.

- Component cost can be dispatched on the functions with the FAC (Functional analysis chart) to lead a Value analysis.

- Link with the Functional dimensioning and your PDM classification

- Copy/paste from FBD or SADT

- Print with WORD, Excel and XML.

- Impact assessment of a component change done via automatic generation of a MS Word report, listing all affected engineering data.

- Automatic generation of a break-down tree : life phases, functions, Design FMEA components in TDC FMEA.

- Graphic filters (all changes in the study since or at a given date, etc.)

- Function, performance criteria, … library management

- Gestion multilingue des données de l’étude.

- Multilingual management of the study data. Interfaces available in: French, English, etc.

- Spellcheck.

- Facilitator annotations: comments on the workgroup life, ‘to do’ tasks or links to files or URL

Tasks input and function characterization done by workgroup members, off meeting.

TDC Structure is useful to implement the following standards and regulations:

- Design FMEA

- APTE method