What are the CSRs “Customer Specific Requirements” in the automotive industry?

Customer Specific Requirements (C.S.R.) are requirements specific to each carmaker or OEM (Original Equipment Manufacturer) in agreement with the supply chain. They guide OEMs and subcontractors in the automotive sector to guarantee customer satisfaction.

CSRs form specific contractual requirements applicable to all products delivered to the customer, in addition to the requirements included in the specifications of each product delivered.

It is important to understand that CSRs are an essential part of the Quality Management System (QMS) created by the I.A.T.F. (International Automotive Task Force) for the automotive industry

QMS elements in the automotive industry

When setting up the QMS, organizations should use the customer’s CSRs as the main source of information. Monitoring CSR updates is also essential. They are considered as a source of requirements complementing IATF 16949.

During the IAFT QMS audit, the organization’s processes are thoroughly checked. An important stage of the audit is reserved for the implementation of CSR. Major manufacturers such as Ford and General Motors insist within IATF on the need to audit their CSRs during IATF 16949 certification audits.

How do you cope with all these different requirements ?

Knowllence’s Robust Engineering Software helps you comply with and deploy CSRs.

Particularly, we monitor their publication and implement them directly in the software. Our customers benefit from regular updates on these rules.

How can we help FMEA facilitators apply the right rules?

To obtain the best results within the deadlines and to avoid having to repeat the analysis, the planning of each project is based on the use of the 5Ts: Intention, Timing, Team, Tasks, Tools.

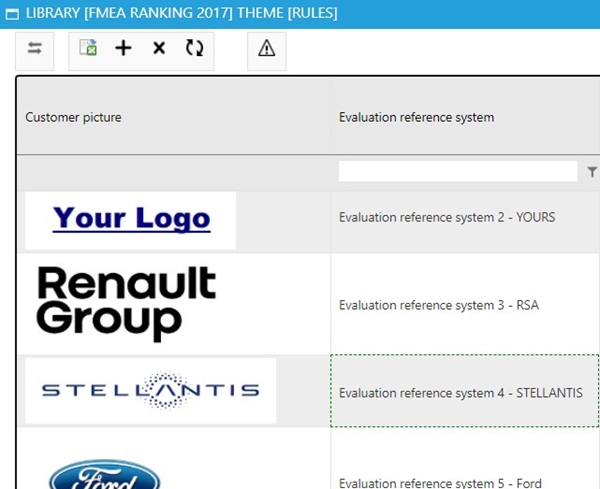

It’s at the start of the study that users configure their CSRs.

Each line in the above list can be selected at the start of the project or changed during the project. This list is not exhaustive. It can be completed directly by a referring user to consider rules outside the CSR.

The ‘YOUR LOGO’ line can be used to define your own rules relating to your internal QMS. The customization of these rules and the update manual are an integral part of our start-up support offer.

The selection of CSRs on a project-by-project basis will have an impact on the following rules in particular :

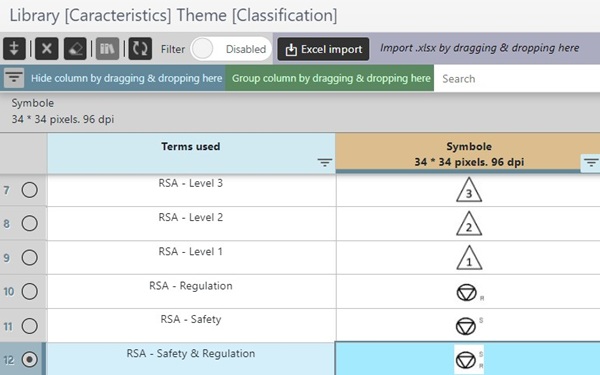

• The list and filtering of classification symbols.

It is the responsibility of each organization to identify special product and process characteristics during the design and development process, in addition to those required by customers and regulations.

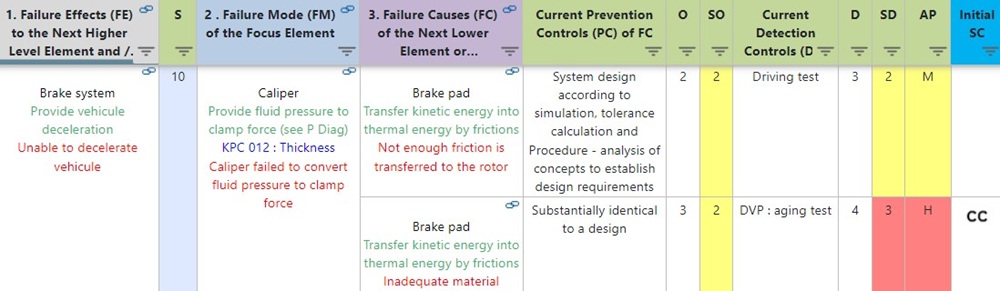

The filtering approach or risk analysis used make it possible to justify the classification or not of each characteristic. To do this, it is necessary to access the right symbols in the FMEA tables, in the product or process characteristics, or in the monitoring plan. For example, the software proposes a filtered list of symbols in line with filtering rules which may be based on severity.

This list is not exhaustive in the software and can be completed at any time by the referring user, particularly in the context of the use of internal symbols specified in your QMS.

• The Severity, Occurrence, Detection rating grids for your Product and Process FMEAs or the Monitoring and Control requirements for your MSR FMEA.

In general, it is to use scales of 10 values between 1 and 10. However, it is possible to customize rules with other ranges. The grids of the main manufacturers are pre-loaded in line with the latest publications. There is no limit to the number of grids in the tool and a column allows you to provide your own examples as recommended by the FMEA AIAG VDA manual.

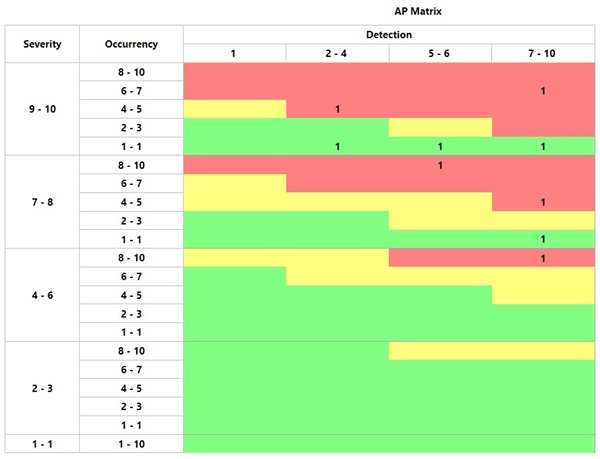

• Evaluation matrix :

Since the publication of the latest FMEA manual in 2019, the IPR standard is tending to disappear and be replaced by the AP standard when the CSRs are published. In our solution, the various AP matrices are loaded (AIAG VDA, Stellantis, BMW, GM….) and there is no limit to the number of alternative matrices. Each referring user can implement and update them.

Alternative criteria are configured to use more advanced rules such as the OS and DS matrices that are presented in the publication of the PORSCHE CSRs for example.

We limit our illustrations to these key points, but you should know that there are other requirements covered by our tool.