APQP and Control Plan: how to comply with AIAG 2024 editions

Since the first of March 2024, the AIAG (Automotive Industry Action Group) has updated and published 2 new handbooks.

For the manufacturers Ford, GM and Stellantis, the implementation must be done by October 2024 (6 months after its publication).

3rd edition of the APQP “Advanced Product Quality Planning”

While the APQP’s goal has not changed, i.e. to ensure that developments meet customers’ requirements in terms of Cost to Quality, the 3rd edition of the APQP manual reinforces several aspects of the product development process.

1st edition of the “Control plan” manual

The AIAG “Control Plan” manual is now separated from the APQP handbook, which highlights its importance.

Monitoring plans are often subject to non-conformities during IATF audits (the first ten non-conformities identified by the International Automotive Bureau of Oversight (IAOB), which is why this handbook was created.

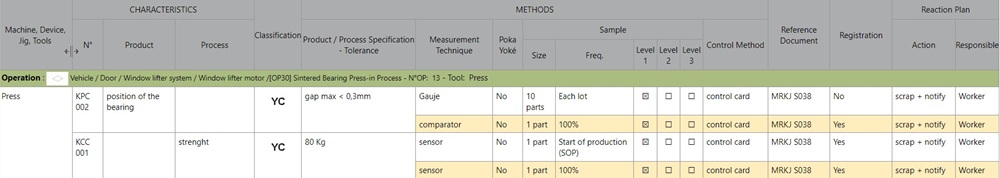

Updating the Control Plan template

The new handbook provides a precise definition of the expectations for each column, whereas it was described briefly in the old one. Only one column has been added, which is the column responsible for the reaction.

We have updated our Robust Engineering software to incorporate these changes and allow our customers to comply.

Please note that our tool allows you to go beyond the requirements to adopt practices observed by most manufacturers. For example, we have the possibility to customize the table to show additional columns :

- Poka-Yoke

- Record

- Consideration of hypertext links

”Links with Flowchart and PFMEA”

The control plan is linked to the PFMEA. It must cover all the stages of manufacturing process and control operation. The handbook specifies how to display the rework and repair processes. All the stages of the process must be integrated, particularly the storage and logistic stages. In connection with the AIAG & VDA FMEA, the conditions requirements for establishing a generic or family-specific monitoring plan are specified.

In our software, the action plan is carried out on the same operation list.

This list can be presented in different ways:

• FLowchart

• Format 3-stage (or more…) structural analysis according to the requirements of step 2 of the AIAG & VDA FMEA handbook.

Our tool also offers different types of locks that allow you to ensure synchronization between:

- Detection of the PFMEA and the content of the Control Plan.

- The classification symbols are assigned to each characteristic throughout the documents.

- The content of the monitoring plan and control ranges. These control charts can be edited in paper version or directly transferred to SPC (Statistical Process Control) tools.

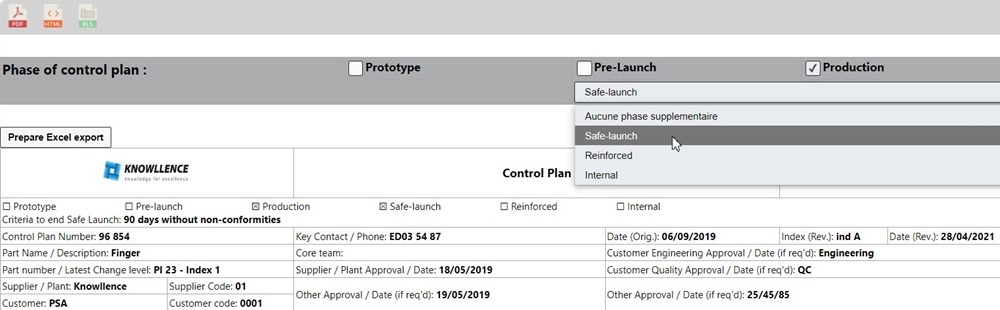

Regarding the Safe Launch phase

A new requirement concerns the “safe launch,” which corresponds to additional checks implemented at the beginning of the production phase or even during the pre-production phase. A criterion is proposed for stopping these checks. This criterion could be, for example, a period of 90 days.

Our tool offers smart phase management and facilitates the reading and consistency of controls from one phase to another. Indeed, there are not 3 different tables, and it is by selection in the phase column that we can put in parallel the controls made for the same characteristic in the different phases.

The “Safe Launch” control phase has been integrated into this tool. A filter allows you to select the phase of the plan control when editing it. It is also possible to highlight the controls needed for Safe Launch.

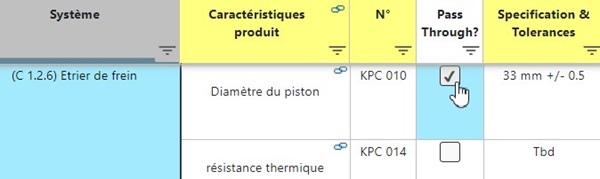

Regarding Pass-Through Characteristics:

In addition to the product, process and special characteristics, a new feature category is added: the pass-through characteristic (PTC). These are features that have a significant impact on your customer and are obtained directly by the process of your subcontractor without modification or validation of your organization. As such, they do not appear in your control plan but in your supplier’s

Regarding the Poka-Yoke in the control plan:

It is clearly established and proved that Poka-Yokes and their validation process must be integrated as lines on their own in the control plan.

It is no longer necessary to maintain additional documentation for this. The frequency and extended column allow you to finally characterize the expected validation process.